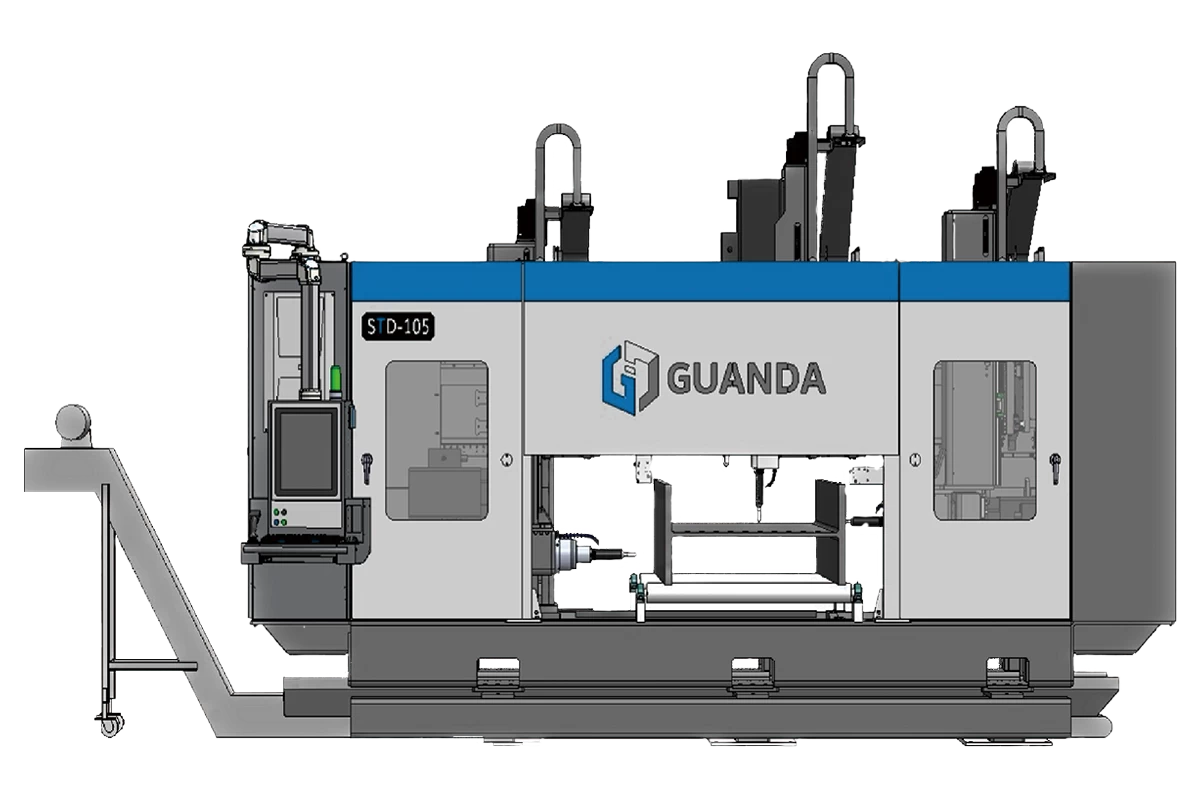

STD Drilling Center

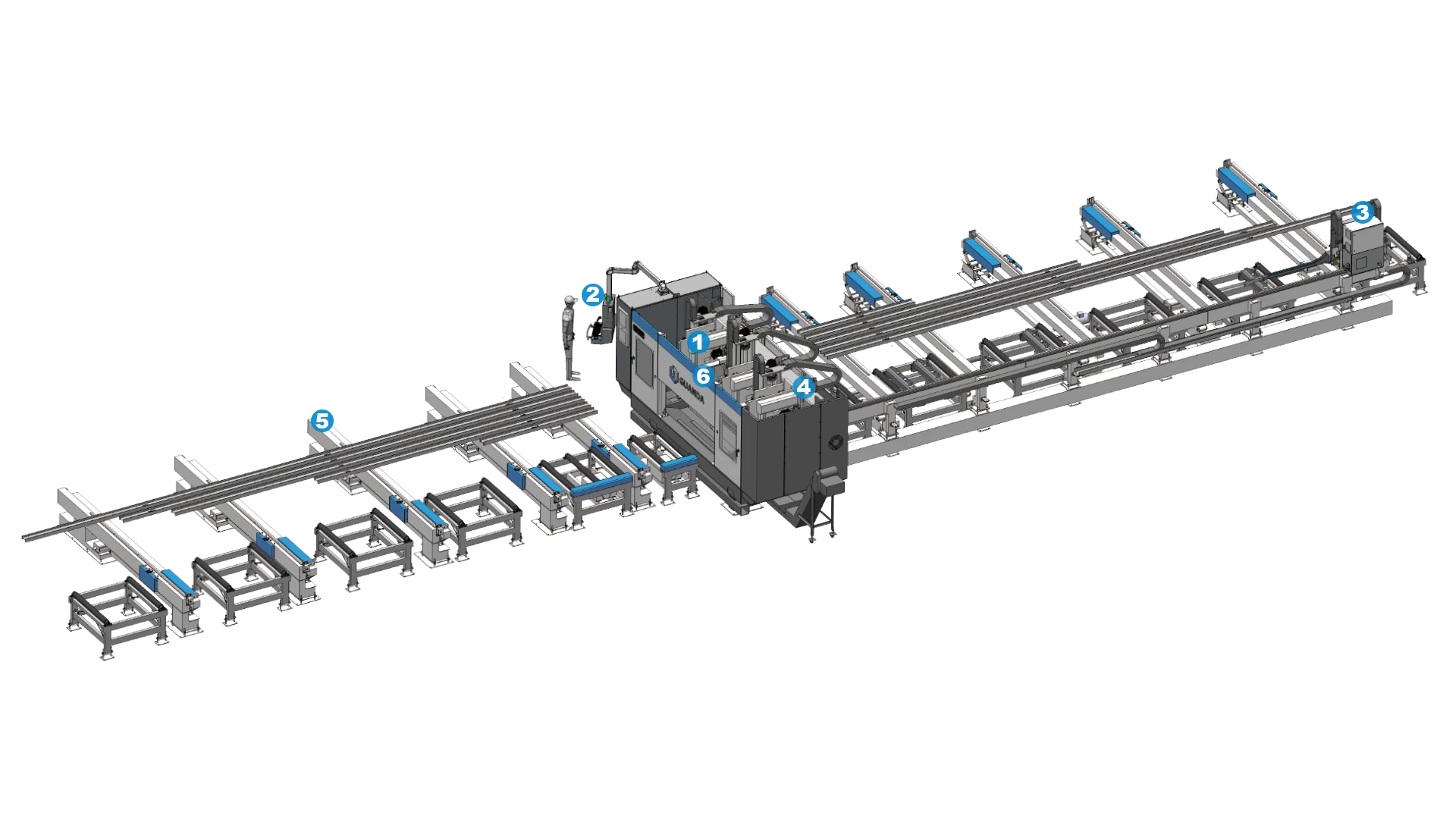

Experience precision and high efficiency with GDM's beam drill line and Auto Beam Drilling Machine. Equipped with 3 sets of 11Kw spindles and 3 sets of BT-40 ATCs, our CNC beam drilling machine ensures superior performance and reliability.

The hydraulic clamping (top/side) provides stability during operations, while the MQL (Minimum Quantity Lubrication) system optimizes lubrication for minimal waste.

The 19" control panel offers easy and intuitive controls, making the process of operating our Steel Beam Drilling Machine both efficient and user-friendly.