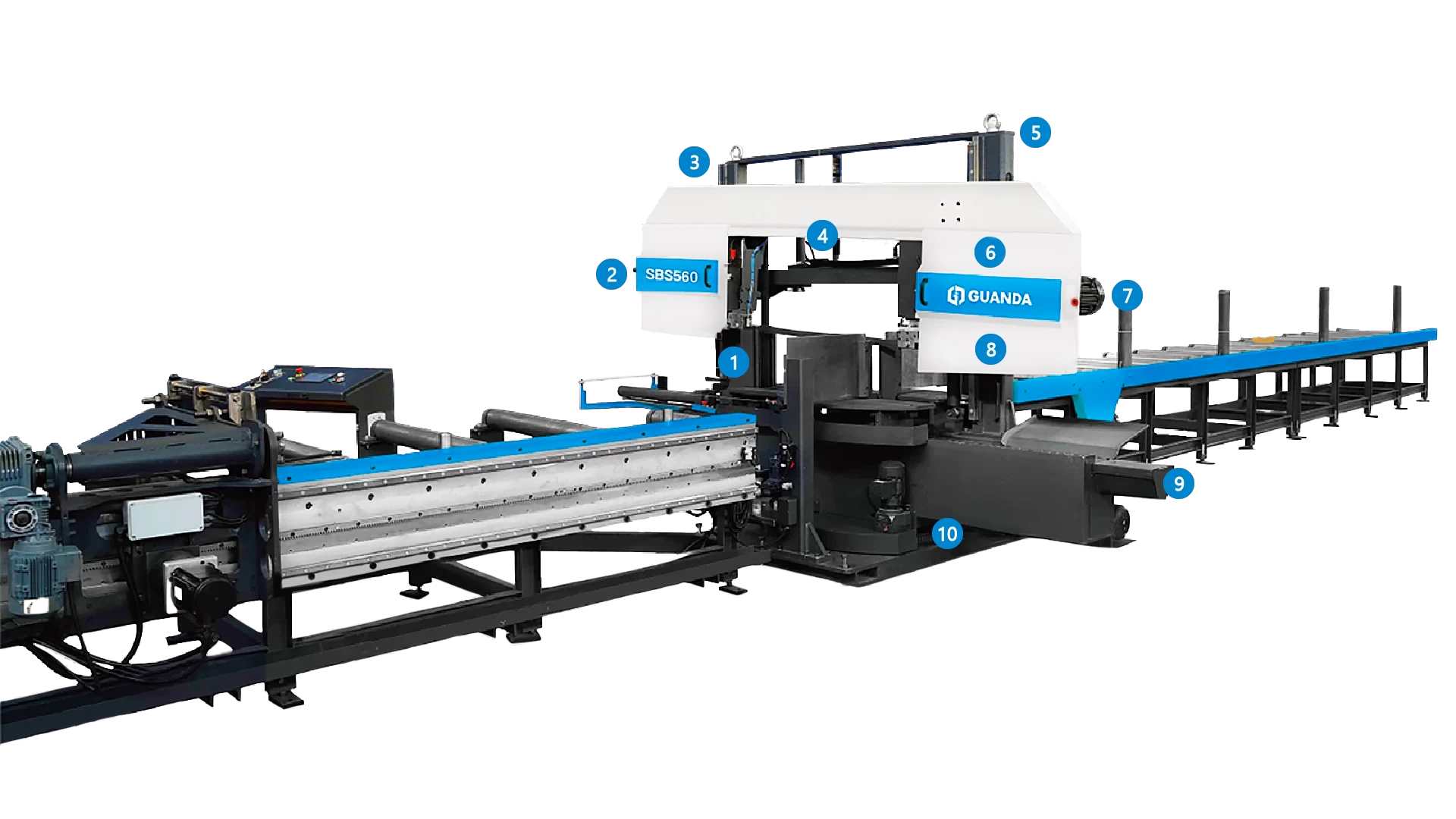

SBS Double Mitre Bandsaw

Robust Processing: The SBS Dual-Angle Band Saw Machine

Redefining Precision and Durability in Cutting In the face of heavy-duty steel processing, stability and precision are the keys to productivity. The SBS Dual-Angle Band Saw Machine features a high-rigidity structure and precision feed guidance, showcasing the pinnacle of cutting craftsmanship.

Whether handling diverse specifications or continuous mass production, it effectively manages load variations to ensure consistent, high-quality cuts every time. Beyond significantly reducing material waste, its flexible angle control provides exceptional processing elasticity.

As a cornerstone of stability, the SBS ensures smooth transitions between processes, building an unshakable foundation for high-efficiency manufacturing.