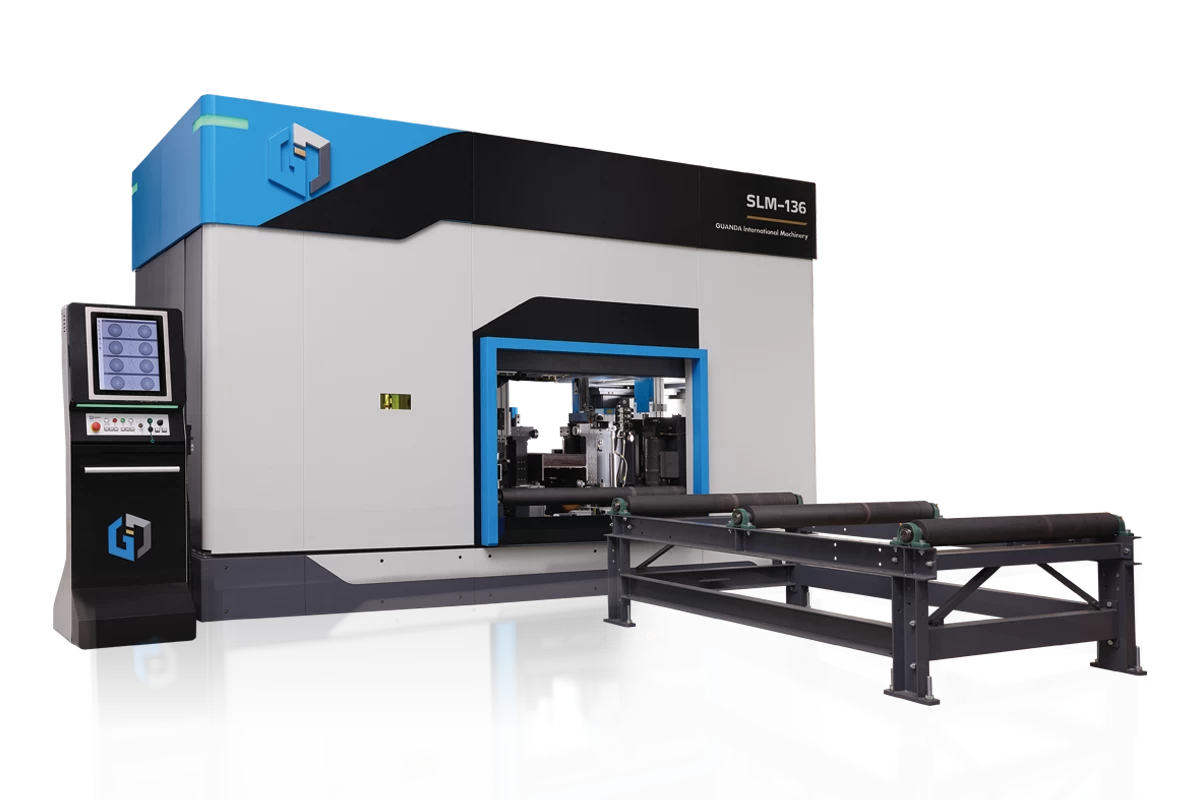

SLM Steel Laser Marking

The SLM Laser Marking Machine: A Digital Foundation for Standardization

In complex steel fabrication, clear and precise identification is the lifeline of quality control. The SLM Series Laser Marking Machine was specifically engineered to replace inefficient manual marking. Utilizing high-stability laser technology, it directly engraves part numbers, processing data, dimensional marks, and precise layout markings (such as drilling coordinates and welding reference lines) onto the steel surface.

This not only grants every beam a unique "Digital Identity" but also provides high-precision visual guidance for subsequent stages, eliminating errors from manual identification and secondary layout. Through real-time synchronization with design data, the SLM ensures total consistency between the blueprint and the physical workpiece, making site management and quality traceability transparent and efficient.