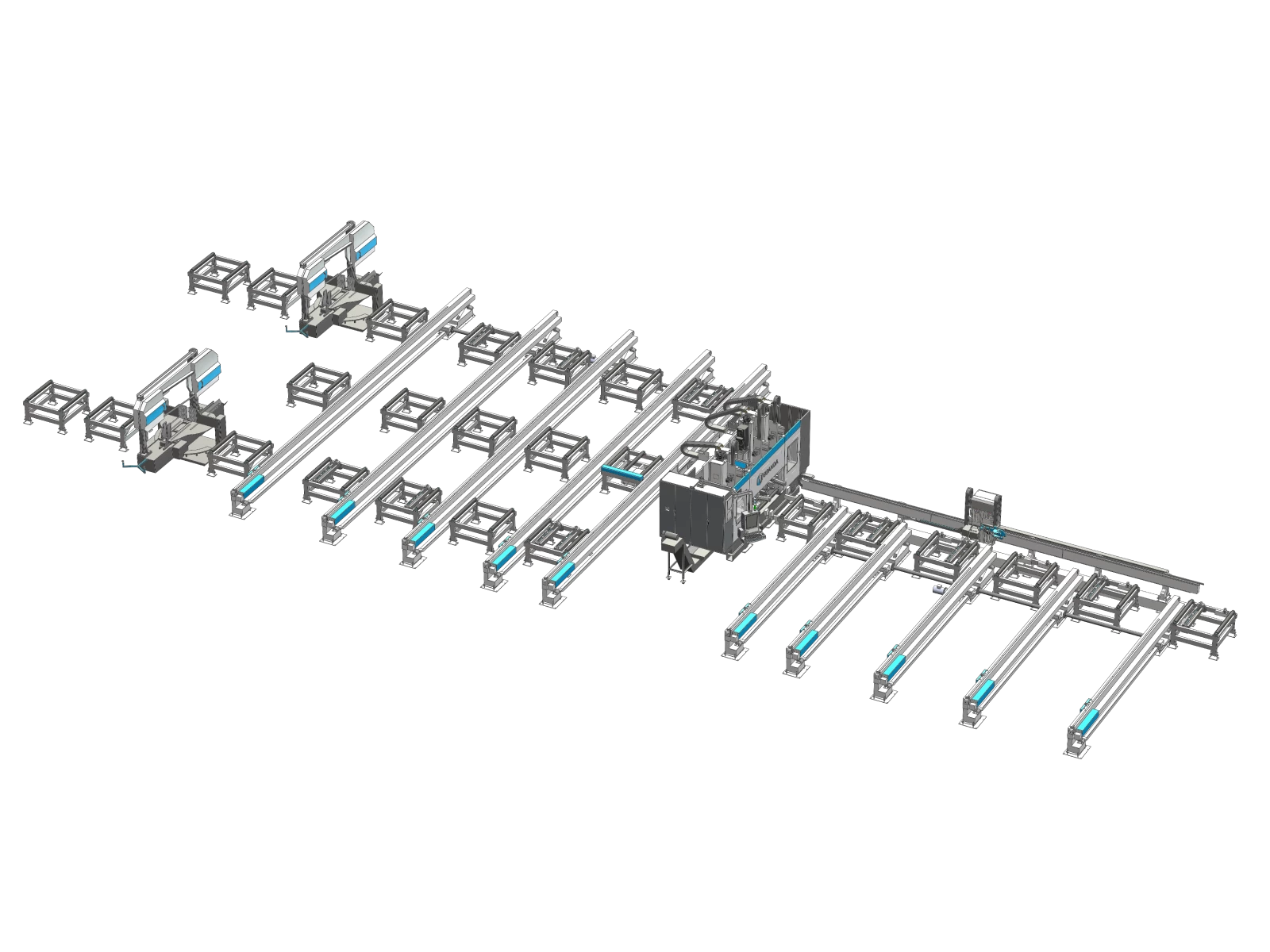

Automated Production Lines: Leading the Next Milestone

Guanda International Machinery’s ultimate vision is to create a "Thinking" automated production line. From laser marking and cutting to the coordinated operation of dual-sided robotic arms, every stage is tightly woven into a systematic workflow. This is no longer just a collection of machines, but a complete, self-evolving solution that adapts to changes and reduces labor dependency. We continue to support enterprises in staying ahead of the wave of smart manufacturing, together opening a high-efficiency future for the steel industry.